Using Hydrogen as fuel provides more significant benefits in the direction of green transportation technology to support zero carbon emission goals as a clean energy source.

Indian Railways will introduce its first hydrogen train aligning with National Hydrogen mission to position India as a global hub for Green Hydrogen production and export. Indian Railways plans to launch about 50 such trains by 2047. The 1st Hydrogen train will operate on the Jind-Sonipat section covering a total of 360kms daily vide 2 round trips. The train will be fuel by India’s largest Hydrogen Refueling station at Jind near to the Railway station.

This initiative is part of a broader effort to enhance the sustainability and efficiency of the national transporter. This move is part of Indian Railways’ broader strategy to reduce its carbon footprint and integrate clean energy solutions into its operations.

A. Project Stakeholders:

- Northern Railways: Owner of the Project.

- Medha Servo Drives Pvt. Ltd., Hyderabad: Northern Railways has awarded to Medha this pilot project for the retrofitment of a Hydrogen Fuel cell on an existing Diesel Electric Multiple Unit (DEMU) rake along with ground infrastructure which is planned to be run on the Jind-Sonipat section of the Northern Railway. Medha entrusted GreenH Electrolysis Pvt. Ltd. the contract to provide the Engineering, Procurement, and Construction (“EPC”) of a Hydrogen production and refuelling station for this important and ground-breaking project.

- GreenH Electrolysis Pvt. Lt, Gurgaon: OEM in PEM Electrolyser technology, a JV company of H2B2 Electrolysis Technologies, Spain. Project scope includes complete Hydrogen Production and Hydrogen Refueling station EPC, integration, interconnection, construction, commissioning, and testing. Scope also includes 5years Long Term Service Agreement (LTSA) with production guarantees and plant availability to Indian Railways.

B. Project Particulars:

- Electrolyser:

- 1MW PEM Electrolyser producing 430kg/day Hydrogen at 40bar and 99.999% purity suitable for use in Fuel Cell Hydrogen tra Containerised solution suitable for ambient -5deg.C to +55deg.C

- Electrolyser manufactured by GreenH Electrolysis Pvt. Ltd. at Jhajjar, Haryana with support from its parent H2B2 Electrolysis Solutions, Spain.

- Produces approx. 430kg/day hydrogen, enough to fuel the Hydrogen train to run more than 400kms per day.

2. Compressor:

- Diaphragm compressor, compressing from 40bar to 500bar. Accompanied by buffer vessel to stabilize the flow. Compressor is in a containerised solution with a main block imported from USA and assembly of the compressor carried out in India.

3. Dispenser:

- H35 Dispenser with TK16 nozzle and infrared communication. Accompanied by T20 chiller. Dispensing 210kg/hr with average flow rate of 3.6kg/min.

- Dispenser allocated for each DPC (driving power car) and dispensers are located 210m away.

- Simultaneous filling into train dispensing total 420kg in 1hour to 2nos. of DPC.

- Dispenser is manufactured in India following all PESO approvals.

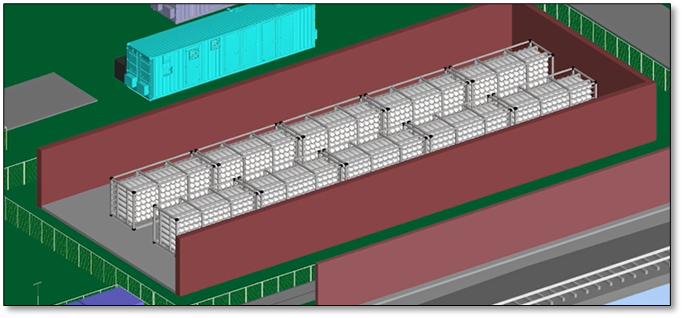

4. Storage:

- Total 3000kgs storage is envisaged which is by far the largest on-ground Hydrogen storage in India.

- 3000s kgs is split into Type-I and Type-IV storage.

- Approx. 2300kgs stored in Type-I steel cylinders at 200bar, which is utilized as a back-up storage. This storage is protected with a 3mtra high fire protection concrete wall.

- Balance 700kgs is stored in Type-IV composite cylinders at 500barg used for daily purpose filling. Type-IV cylinders are better suited for high pressure storage and used for continuous refueling. Being composite cylinders, embrittlement issues are negated. These are again split in 2 parts catering to each dispenser.

C. Challenges faced:

- Longest train with 2 dispensers located 210 mtrs away.

- Filling both coaches at same time within same time limit

- 1st time approval of 500bar Type-IV cylinders

- Largest on ground high pressure Hydrogen storage of 3000kgs

- Complicated fueling protocol

D. Mitigation plans:

- Comprehensive planning to get the approval of Type-IV 500bar cylinders by PESO. Lots of documentations, design approvals, drawing reviews, factory visits, final acceptance tests etc. are carried out timely for a smooth execution of the project.

- Developing multiple fueling simulations, and devising the most complex and accurate fueling simulation, employing Tk16 nozzle with infrared communication ensuring Hydrogen temperatures inside the train cylinders within prescribed limits.

- Employing trench hydrogen piping and cabling with protective fencing all around the 210m length prohibiting invasions and for a safer plant operation.

The execution of this groundbreaking project is ongoing and in full swing by GreenH Electrolysis Pvt. Ltd. which post commissioning in this year 2024, will pave the way and set an example for many such Hydrogen projects in India. India’s 1st Hydrogen train set project is of national importance and heralds a new era for the Indian Railways. This ambitious project signifies India’s commitment towards a cleaner and greener future.